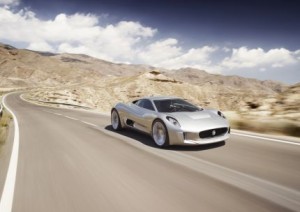

Jaguar introduced a stunning new electric supercar at the recent Paris auto show and it attracted so much attention, that the company is considering a limited production of the Jaguar C-X75 concept.

Jaguar introduced a stunning new electric supercar at the recent Paris auto show and it attracted so much attention, that the company is considering a limited production of the Jaguar C-X75 concept.

Created to celebrate its 75th anniversary, the C-X75 is shorter and lower than most existing supercars.? Its exterior design is about pure performance with a simple central fuselage surrounded by prominent wheel arches. The absence of a conventional piston engine allowed designers the freedom to rearrange the mechanical components ??and creating the most elegant engineering package available.

?The C-X75 is everything a Jaguar should be. It possesses remarkable poise and grace yet at the same time has the excitement and potency of a true supercar. You could argue this is as close to a pure art form as a concept car can get and we believe it is a worthy homage to 75 years of iconic Jaguar design.??Ian Callum, Design Director, Jaguar Cars.

The 205mph four-wheel drive supercar is capable of running in purely electric (zero tailpipe emissions) mode for 68 miles on a six-hour domestic plug-in charge. The innovative, lightweight micro gas-turbines are also capable of very quickly and efficiently recharging the Lithium-ion batteries, giving the car a theoretical range of 560 miles.? C-X75 is capable of reaching 205 mph sprinting from 0-62 mph ?in just 3.4 seconds.

This remarkable range-extension system is a result of Jaguar?s research engineers adopting a clean-sheet approach to the question of powering the supercars of the future. The C-X75 turns to the very latest evolution of a pioneering British technology: the gas turbine.

This remarkable range-extension system is a result of Jaguar?s research engineers adopting a clean-sheet approach to the question of powering the supercars of the future. The C-X75 turns to the very latest evolution of a pioneering British technology: the gas turbine.

Developed in partnership with Bladon Jets, the miniaturized turbine blade – the first viable axial-flow micro-turbine – increases the compression and efficiency of micro gas-turbines to the point at which they can be viewed as a realistic power source. Each of the micro gas-turbines weighs just 35 kg and produces 94-hp (70kW) of power at a constant 80,000rpm.

The energy created by the turbines and stored in the batteries is transmitted to the road using four independent electric motors. Using individual motors has benefits in terms of weight-saving and distribution, packaging and efficiency. Each motor weighs just 50kg but produces 195-hp of power and combined torque output of 1,180-lb.ft.

Because each wheel is driven by its own electric motor, the C-X75 is four-wheel drive ? with all the traction, grip and safety benefits that entails ? without the weight disadvantages of a purely mechanical set-up. Inherent in this drivetrain is the ability to independently vector torque to each wheel across the full speed range. This offers potential benefits in terms of stability and control, creating an infinitely and instantaneously adjustable traction and stability control system.

With the seats fixed, the steering wheel, controls, main binnacle and pedal box all adjust towards the driver. The seats are attached to the bulkhead as in a single-seater racing car, and air to feed the turbines passes smoothly around them via channels in the structure of the body.

With the seats fixed, the steering wheel, controls, main binnacle and pedal box all adjust towards the driver. The seats are attached to the bulkhead as in a single-seater racing car, and air to feed the turbines passes smoothly around them via channels in the structure of the body.

A new interface for the driver has also been created for the C-X75 using high-resolution TFT screens. Building on Jaguar?s 10-year expertise in touchscreen technology, the Jaguar Co-Pilot display in the centre console supports the driver in extracting the full potential of the C-X75 by seamlessly managing information.

The main driver information screen is housed within the instrument binnacle. Needles float on the periphery of the twin cowls and sweep round the outer edge to display the status and rpm of the two turbines. The design team combined designs from instrumentation in the new XJ saloon with those from fighter aircraft to create virtual 3D ?gimbals? around which the gauges wrap and rotate to provide status updates.

According to AutoWeek magazine, Jaguar is crunching numbers on a limited quantity of up to 2000 cars, but production will require five to seven years, while the Blandon Jets micro gas-turbine technology is integrated into the vehicle.? Actually, the cost of developing the turbines is less than an equivalent internal combustion engine, says Tony Harper, the head of Jaguar advanced powertrains. ?With a 100 times fewer parts in a turbine than in an internal combustion engine, there is much less to go wrong.